Case Study

Post Merger Integration and Operational Excellence

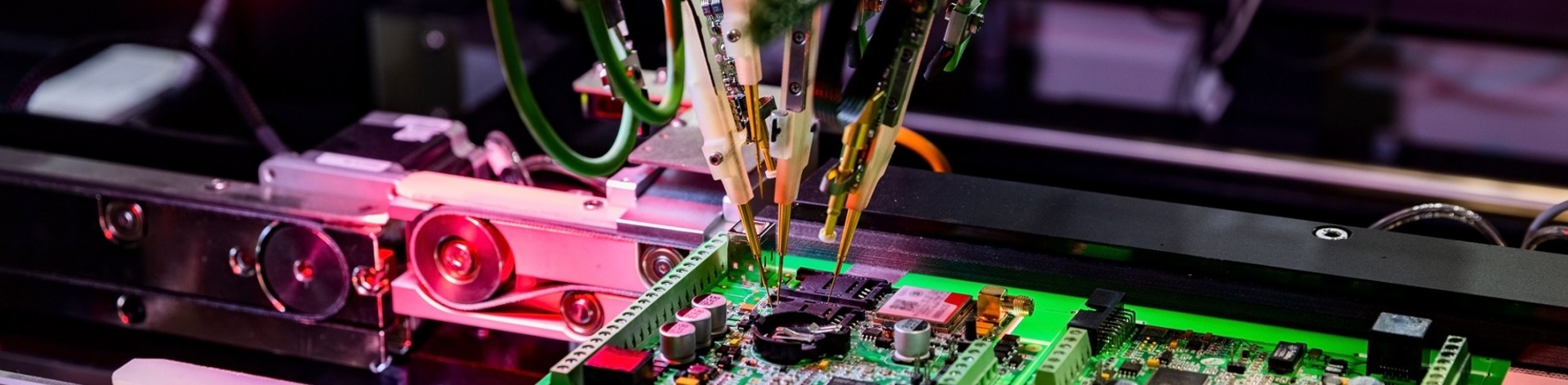

Optimization of production and supply chain in the context of post-merger integration of a medium-sized automotive electronics company in Germany.

The Client

A medium-sized manufacturer of automotive electronics took over a competitor that had run into difficulties. With the completion of the transaction, it became apparent that, in addition to external factors, internal, operational reasons were also responsible for the economic problems. This made it necessary to implement a short-term package of measures to improve earnings at the same time as the integration into the absorbing company (post-merger integration).

Management identified the greatest potential for improvement in production and supply chain management (SCM), so efforts were initially focused on these areas.

The Challenge

The acquiring company was lean and had neither the necessary resources nor experience with the integration of distressed companies.

The acquired company had a comparatively young management team and showed the typical characteristics of a company in crisis: key performers had left the company, necessary investments and maintenance measures had not been carried out for a long time and motivation in parts of the workforce was very low.

The situation was further complicated by the turbulence caused by the Corona pandemic: staff absences due to illness, disrupted supply chains and economic difficulties on the part of suppliers. On the customer side, the situation was compounded by the fact that car manufacturers were changing their call-offs at very short notice.

The Solution

Against this background, an experienced interim COO was hired, who had many years of practical experience in production and supply chain management as well as PMI skills. First of all, he took stock of the situation and identified strengths and weaknesses, opportunities and risks. From this, measures were derived that were evaluated and prioritized according to their impact on results, investment requirements, implementation speed and risks.

Particularly important was the early and comprehensive involvement of all stakeholders: Management team and employees, the relevant functional managers in the new parent company, suppliers and customers. This made it possible to create transparency, improve communication and create a constructive working environment. In close cooperation with all stakeholders, the prioritized activities were implemented under the leadership and coordination of the interim manager.

The Results

After more and more success in involving and motivating all stakeholders during the first weeks, significant improvements were achieved across the board. In addition to major individual measures, such as increasing plant productivity (OEE) and reducing absenteeism, dozens of smaller, operational measures were implemented, which together also meant significant optimization.

The decisive success factor was the recognition of the interim manager's technical competence and leadership personality, who objectively mediated and coordinated between the parties involved and then consistently ensured implementation - even in the face of resistance. In this way, the goals set at the beginning of the project for a sustainable improvement in cash flow and operating results were actually realized.