“Return-to-work” implies a going back to where we were. Is there a “going-back” or are we simply moving toward a whole new reality? In conversation with human resource leaders across the U.S., Boyden's Steve Nilsen explores cross-sector return-to-work strategies.

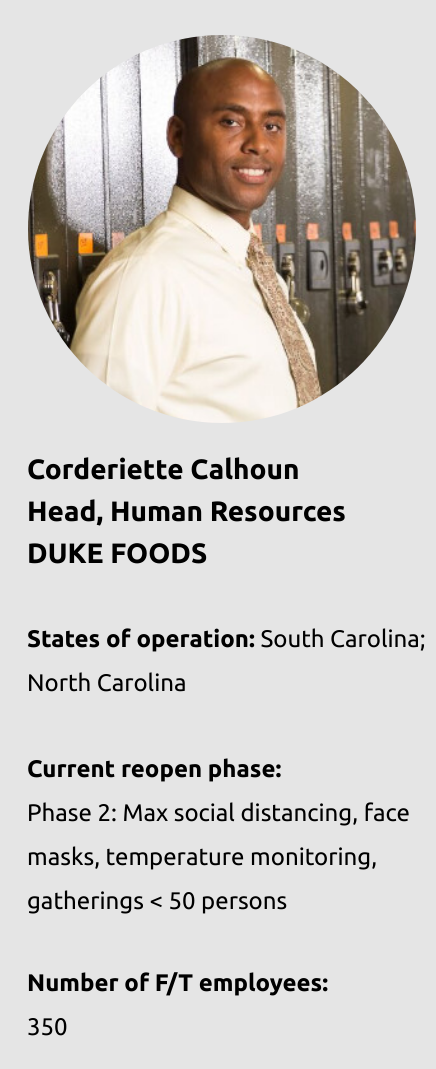

This issue of HR: Return Strategy features Corderiette Calhoun, Head, Human Resources of Duke Foods.

Nilsen: Is there a “going-back”?

Calhoun: We are certainly moving towards a new reality. The COVID-19 pandemic pushed us out of our comfort zone from a business perspective, forced us to pivot and accept new ways of thinking and doing things. The preventative and health safety measures we have implemented will continue. They will keep our employees safer and will allow us to react faster to business interruptions in the future.

Nilsen: What are the biggest changes you have implemented to continue operating? In your return-to-work plan, what will remain as a COVID-19 legacy?

Calhoun: We conduct temperature checks on manufacturing staff twice daily, employ social distancing and have mandated face masks or face shields. We have also implemented remote break areas and we retest an employee as they return to work after an absence due to sickness. As I mentioned earlier, all of these measures are preventative and designed to prevent the introduction of the virus and slow or stop the spread in our food manufacturing facility.

Nilsen: What metrics are you tracking to help guide your organization’s return-to-work? Are you implementing new related internal metrics?

Calhoun: The additional metric we are tracking now vs. before the outbreak is the rate of infection and sickness among our staff. We track and report this daily.

Nilsen: In what new ways are you using technology in your return-to-work strategy?

Calhoun: We use infrared thermometers to be able to monitor staff twice per day. Like others, we have become heavy users of video conferencing tools. We have also deployed new technology to support us in job creation including revamping our sourcing strategies impacted by COVID-19 through online shopping, digital and contactless payment and remote work. COVID-19 has also significantly impacted the global supply chain. We have implemented Supply Chain 4.0 to combat disruptions from COVID-19 by faster and more visible supply chain data via technologies like cloud computing, Internet of Things (IoT), Big Data Analytics and AI.

Nilsen: What do you anticipate will be the greatest obstacle in the return-to-work phase?

Calhoun: Since we produce food, we were categorized as an essential business. In that sense, our return to work is essentially what we are already doing. The challenges are always to reach 100% monitoring of sickness, conduct testing, and ensure a safe return-to-work of an employee who has been ill.

Nilsen: What is your greatest learning from this so far, and what advice would you offer as we continue to navigate these unchartered waters?

Calhoun: Training of Supervisors and Managers is critical. They need to know what to look for in their teams so they can move rapidly to address symptoms inside a facility. Making masks and frequent temperature monitoring mandatory is critically important as well.

Read Issue 1 of HR: Return Strategy with Cathleen Allred, SVP, HR, Renfro